How A Diesel Engine Works With Don Seddon

Book Extract

The diesel is the simplest of all engines, which is one of the main reasons for its reputation as the most reliable power source for ships and boats. Despite all the technological advances made by man, simplicity is still the key to reliability.

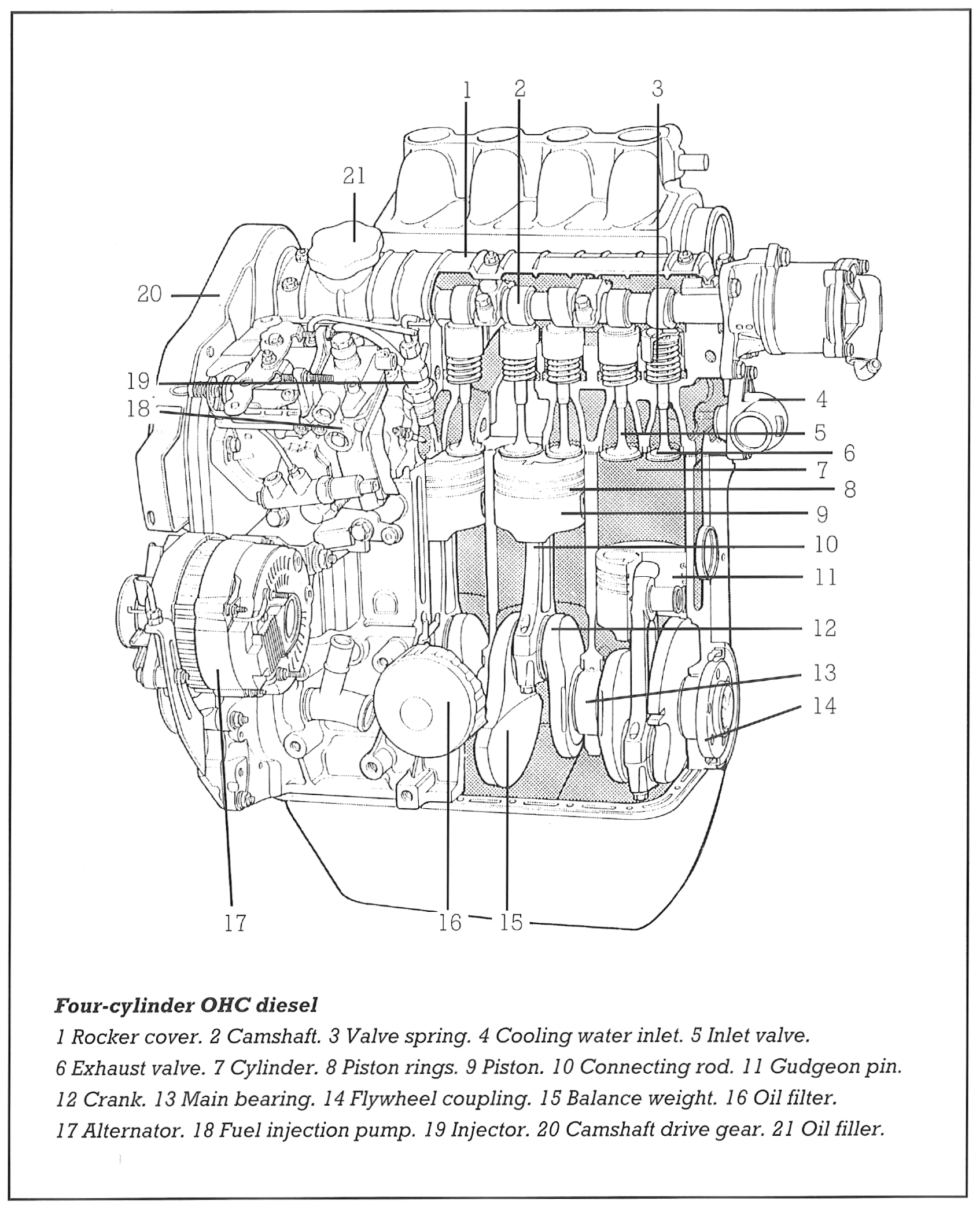

At its most basic, the diesel needs only fuel and air to operate. There is no electrical ignition system: the engine works on the principle that if you compress a gas its temperature rises. This, incidentally, gives the diesel its alternative name of compression ignition engine, to distinguish it from spark ignition (petrol) engines. In a diesel, the fuel is injected into a cylinder containing superheated compressed air. The heat ignites the fuel- air mixture, which expands as it burns, and the resulting pressure drives a piston downwards. The piston is connected by a rod to a crankshaft, which converts the downward thrust of the piston into the rotary torque needed to drive the propeller.

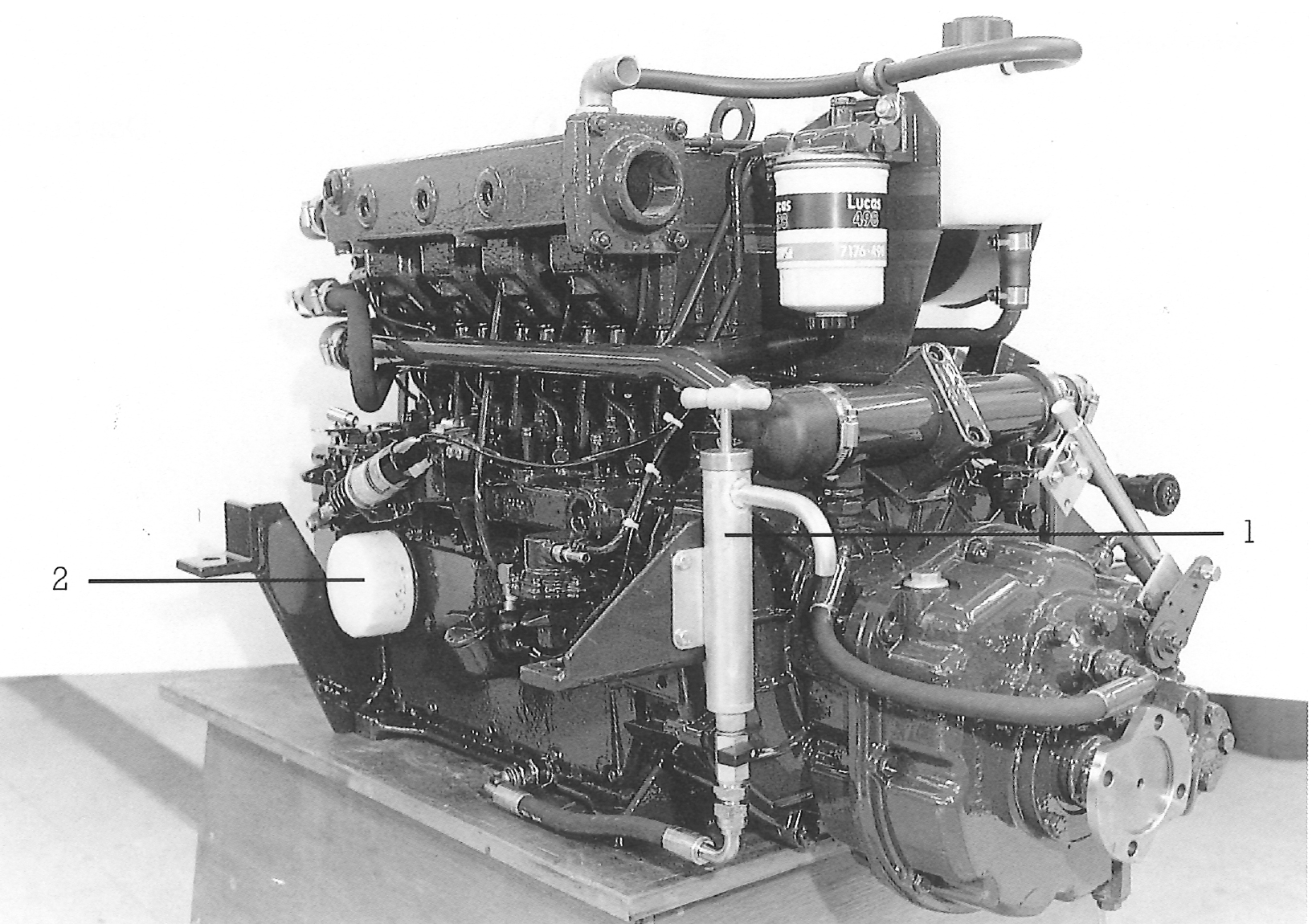

This gearbox-end view of a four-cylinder marine diesel shows the built-in brass oil-change pump (1) and screw-in oil filter (2) with starter solenoid immediately above it.

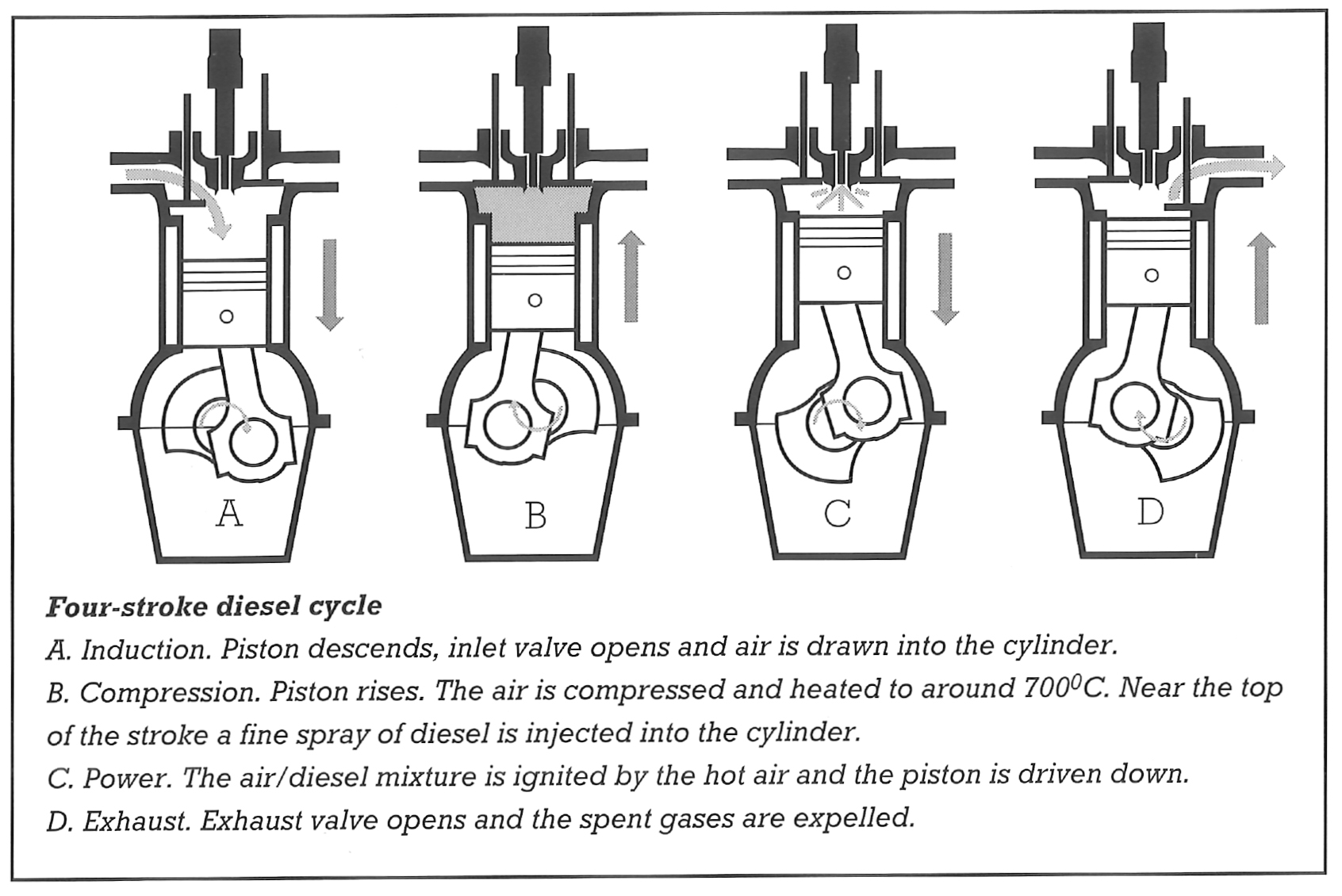

Four-stroke diesel cycle

There are some two-stroke diesel engines, but the majority operate on the four-stroke cycle. As its name implies, the full cycle consists of four strokes of the piston, two upward and two downward: induction, compression, power and exhaust. This gives one power stroke per two revolutions of the crankshaft.

The illustration above shows the full sequence, beginning with the induction stroke. As the piston descends the inlet valve opens and a charge of air is drawn into the cylinder. When the piston reaches the bottom of its stroke the valve closes. The piston now starts travelling upwards on the compression stroke, pressurising the air trapped in the cylinder. By the time the piston reaches the top and all the air has been squeezed into the combustion chamber at the top of the cylinder, the temperature of the air will have risen to around 500-700°C.

At this point fuel is injected into the combustion chamber in the form of an atomised spray. The hot air and fuel mixture ignites in a controlled explosion, the pressure forcing the piston down again on its power stroke. After the power stroke the piston rises on the exhaust stroke, propelled by the still- turning crankshaft. As it rises the exhaust valve opens and the burnt gases are expelled. At the top of the stroke the exhaust valve then closes and the cycle begins again. The temperature generated in the combustion chamber depends on how much the air is compressed – normally between 16:1 and 25:1 for diesel engines.. This figure, the compression ratio, is calculated by dividing the volume of the combustion chamber when the piston is at the top of its stroke into the volume of the much larger enclosed space when the piston reaches the bottom of its stroke.

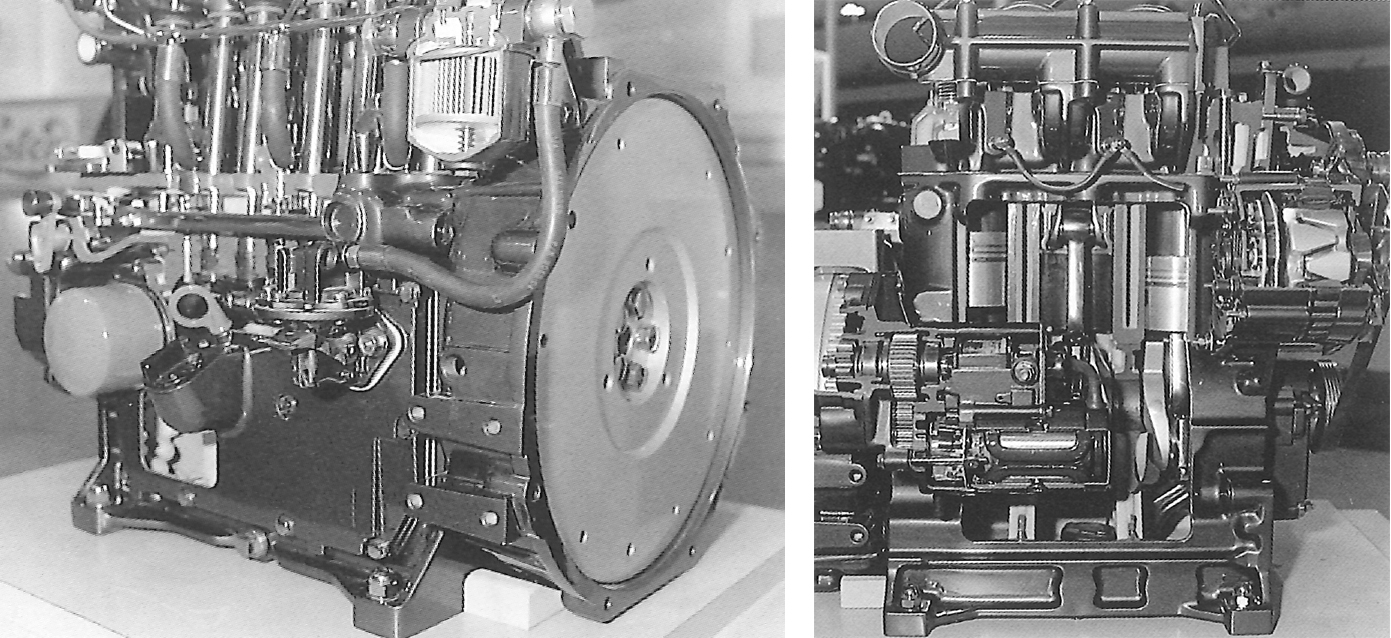

The Lister Alpha range was designed specifically for small boats and will develop from 20-40hp.This cutaway example for exhibition use shows the rugged cylinder construction necessary to withstand the forces of compression. Note too the fine filter (top right, above) and the heavy flywheel to smooth output.

All four-stroke engines need a weight in the form of a flywheel to carry the crankshaft smoothly through the three non-power strokes. When the engine first fires, the initial power stroke turns the crankshaft, after which the momentum of the flywheel keeps the crankshaft turning, driving the piston up and down, until the next power stroke.

A single-cylinder engine needs a large flywheel relative to its size. Because a multi-cylinder engine staggers the piston power strokes there is less work for the flywheel, which can be correspondingly smaller and lighter. For added smoothness, crankshafts also incorporate balance weights and are statically and dynamically balanced to keep out-of-balance forces to a minimum. In some cases secondary balance shafts are incorporated, driven from the crankshaft. These directly counterbalance the forces created by the power stroke, reduce engine vibration and thus enable a lighter flywheel to be used. Geared to the crankshaft, and therefore rotating as it rotates, are the high pressure injection pump, the camshaft which controls the inlet and exhaust valves, the fuel lift pump, the water pumps and the alternator.

The quality and efficiency of combustion, and therefore the power developed, is determined by the quantity of fuel injected (controlled by the throttle setting), the diameter (bore) of the cylinder and the distance travelled by the piston (stroke), and the design of the combustion chamber. The actual output torque (turning force) at the crankshaft will also depend on the engine load, ie how much it is being required to work.

Four-cylinder OHC diesel

© Not to be reproduced without written permission from Fernhurst Books Limited.

Diesel Troubleshooter For Yachts is written by Don Seddon. Don Seddon is a Chartered Engineer and has been a recreational sailor for 35 years and a commercial yacht skipper for 12 years. As well as his interest in engines and sailing, he is an experienced hydraulic engineer.